Engineering Filament 0.5KG Refill Mystery Box

Engineering Filament 0.5KG Refill Mystery Box

What's Inside:

A random selection of filament from our Engineering Filament Series.

Available Sizes: 0.5KG Refill * 5 rolls per box

Possible Filament Types: Nylon PA6/66, PA6-CF, PA6-GF25, PA12-CF, PC-ABS

Important: Filament types will be randomly selected.

Choose options

Engineering Filament 0.5KG Refill Mystery Box

What's Inside:

A random selection of filament from our Engineering Filament Series.

Available Sizes: 0.5KG Refill * 5 rolls per box

Possible Filament Types: Nylon PA6/66, PA6-CF, PA6-GF25, PA12-CF, PC-ABS

Important: Filament types will be randomly selected.

Engineering Filament 0.5KG Refill Mystery Box

What's Inside:

A random selection of filament from our Engineering Filament Series.

Available Sizes: 0.5KG Refill * 5 rolls per box

Possible Filament Types: Nylon PA6/66, PA6-CF, PA6-GF25, PA12-CF, PC-ABS

Important: Filament types will be randomly selected.

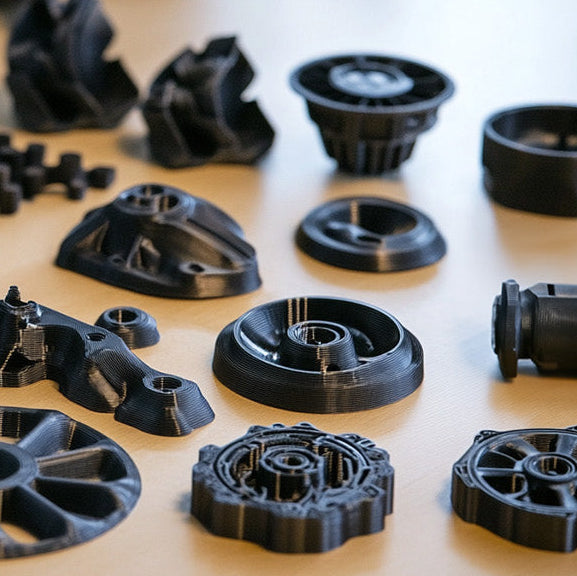

Filament Mystery Box - Unlock the Surprise!

Unbox a mystery selection of filaments from our Engineering Filament Series. Each order may include:

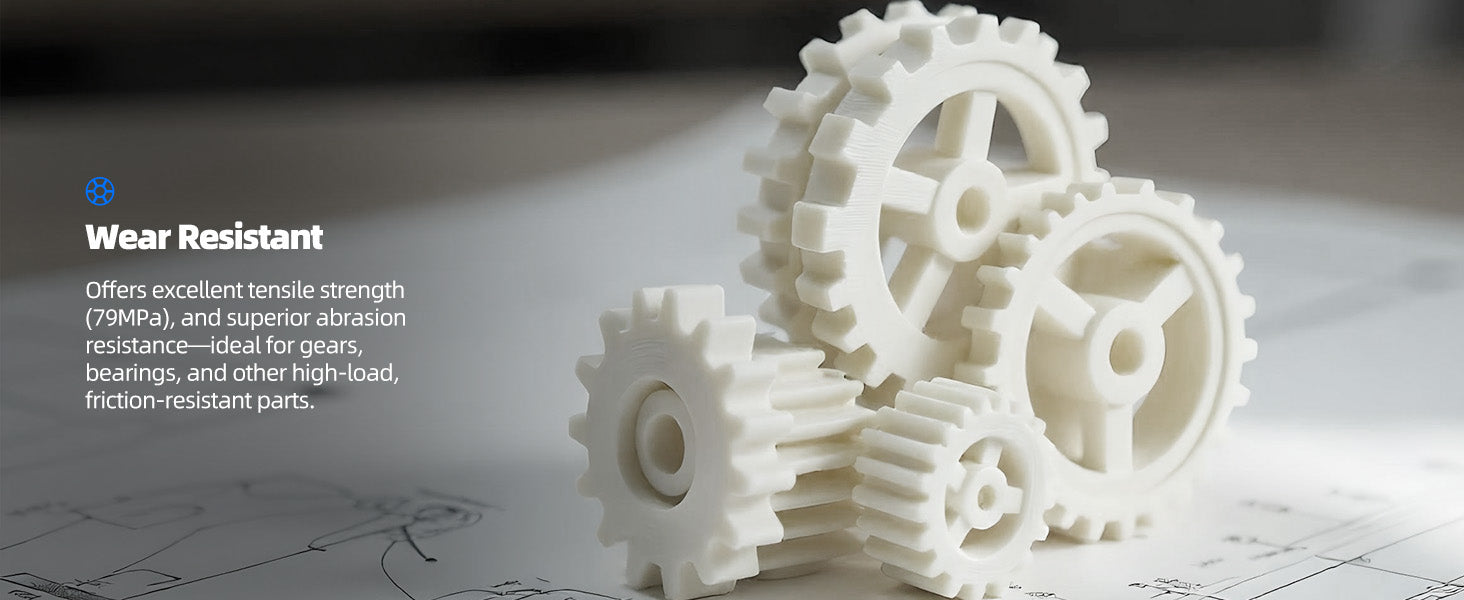

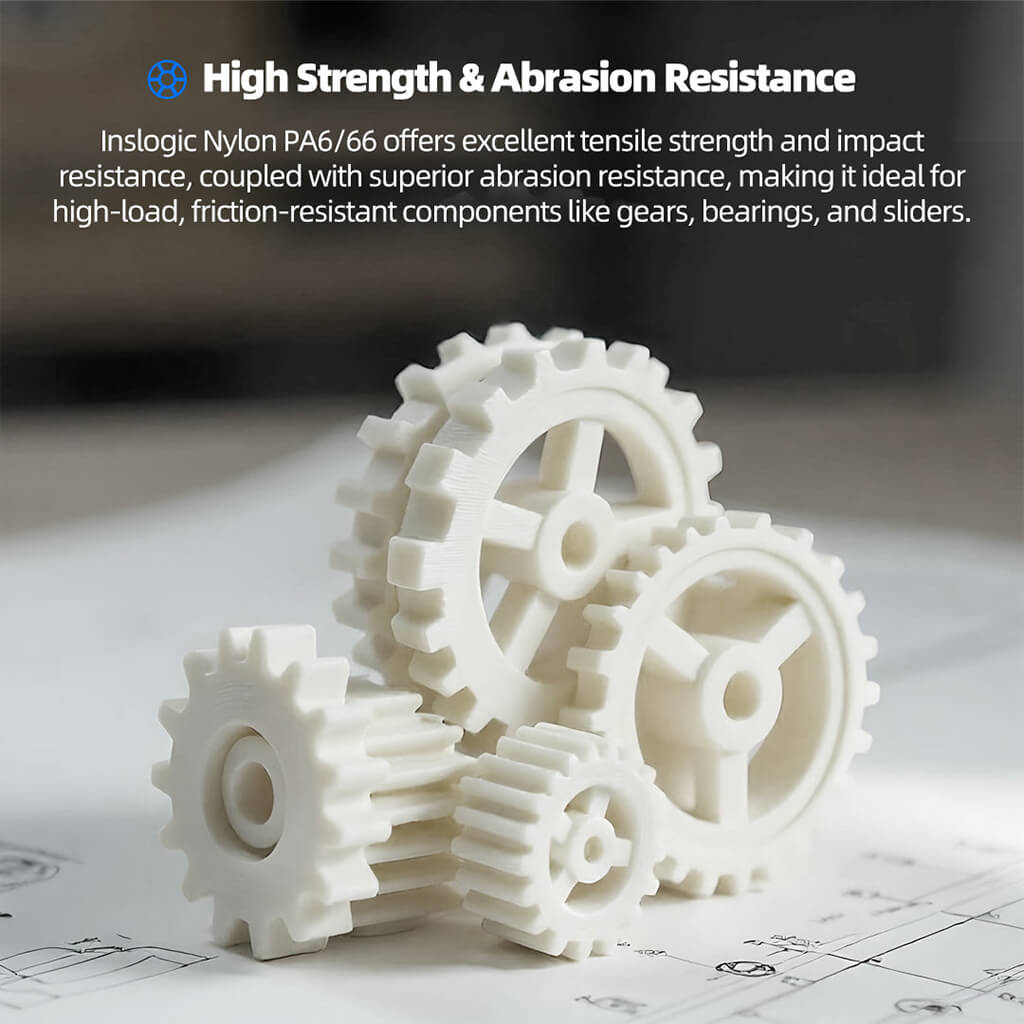

Nylon PA6/66: Lower warping, improved layer adhesion, and good tensile strength

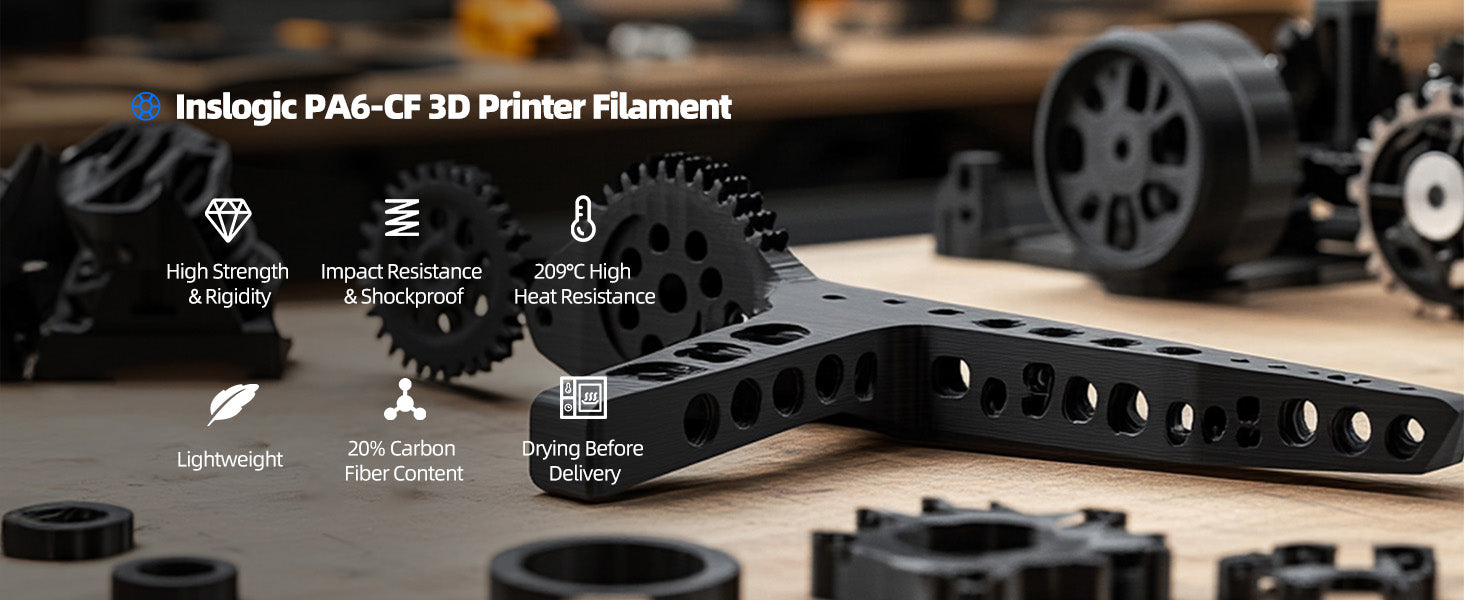

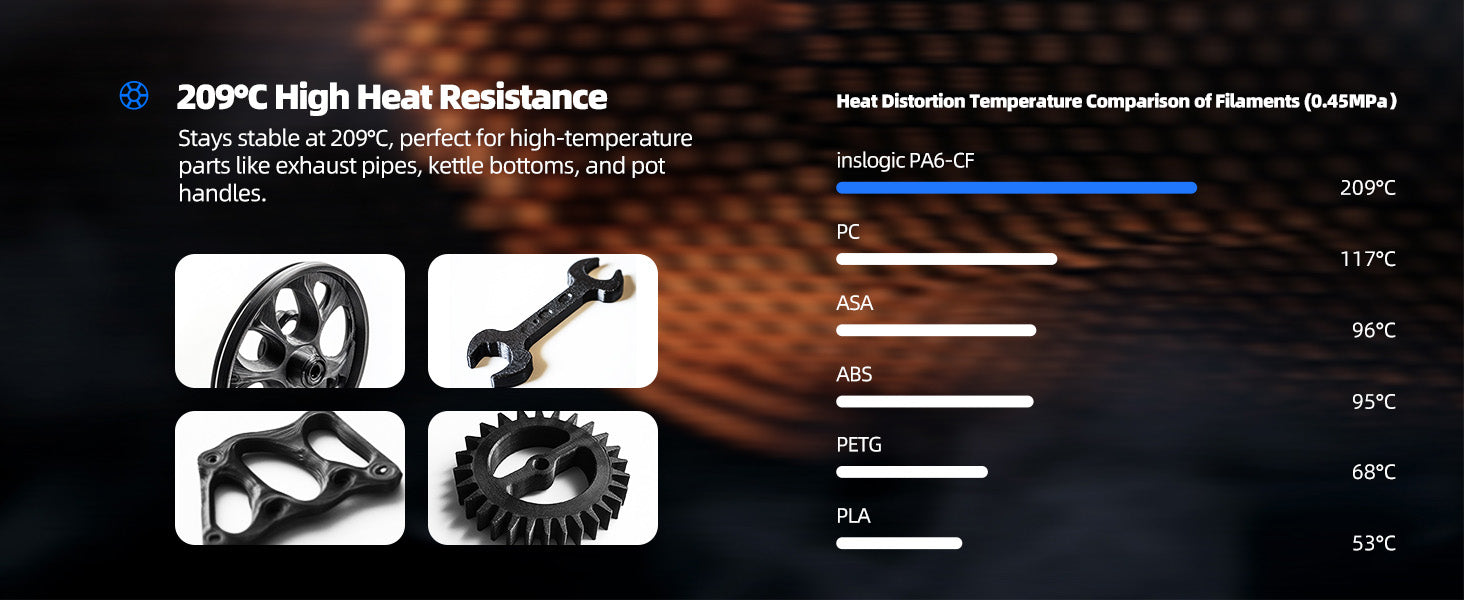

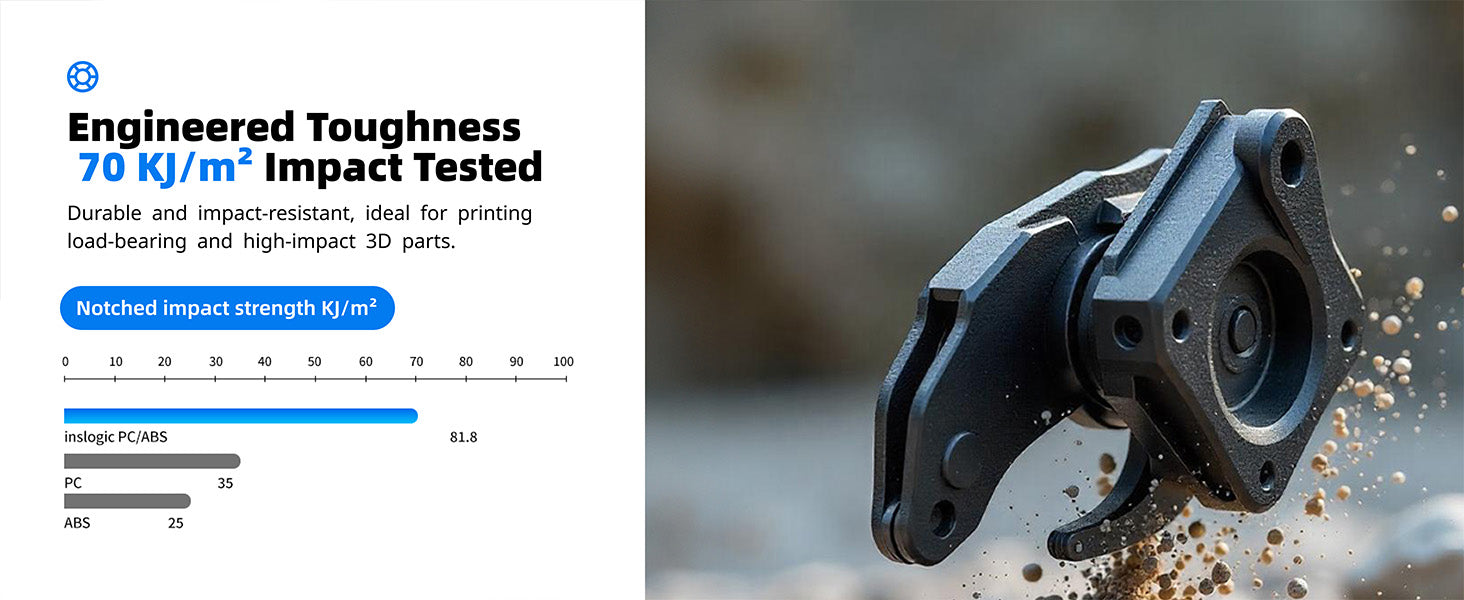

PA6-CF: High Toughness & Impact Resistance

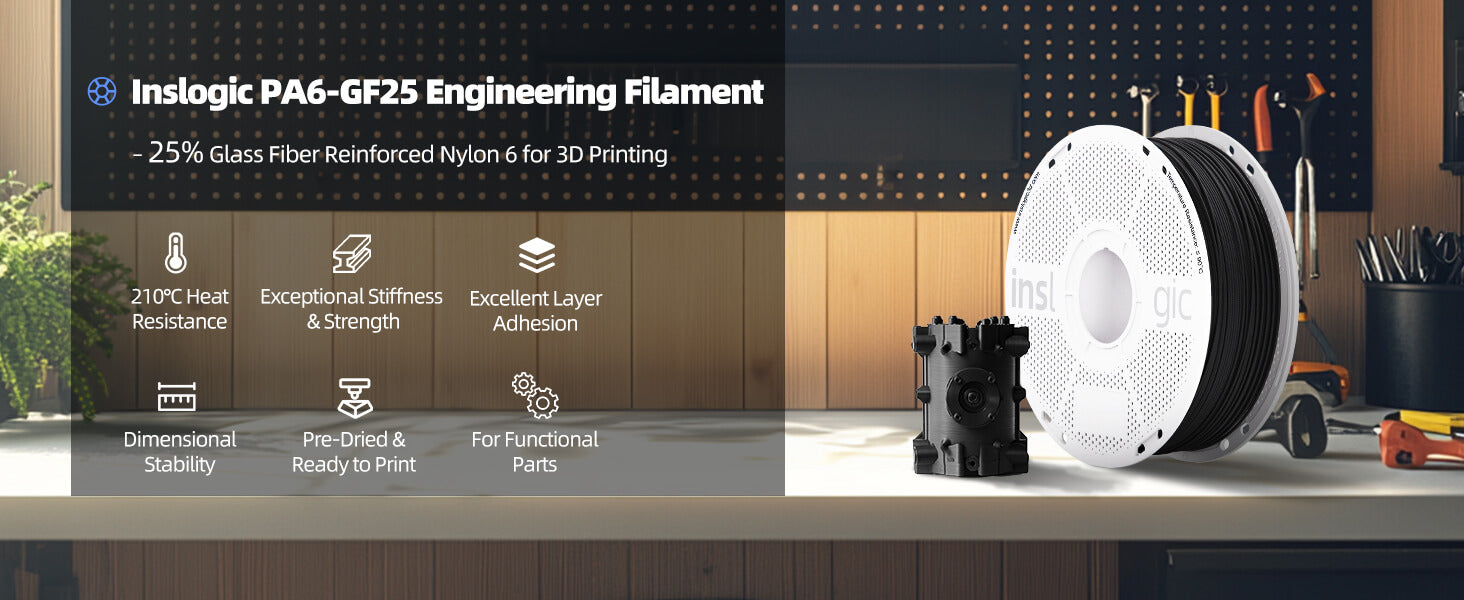

PA6-GF25: Reinforced with 25% glass fiber, prints with high rigidity and low warping

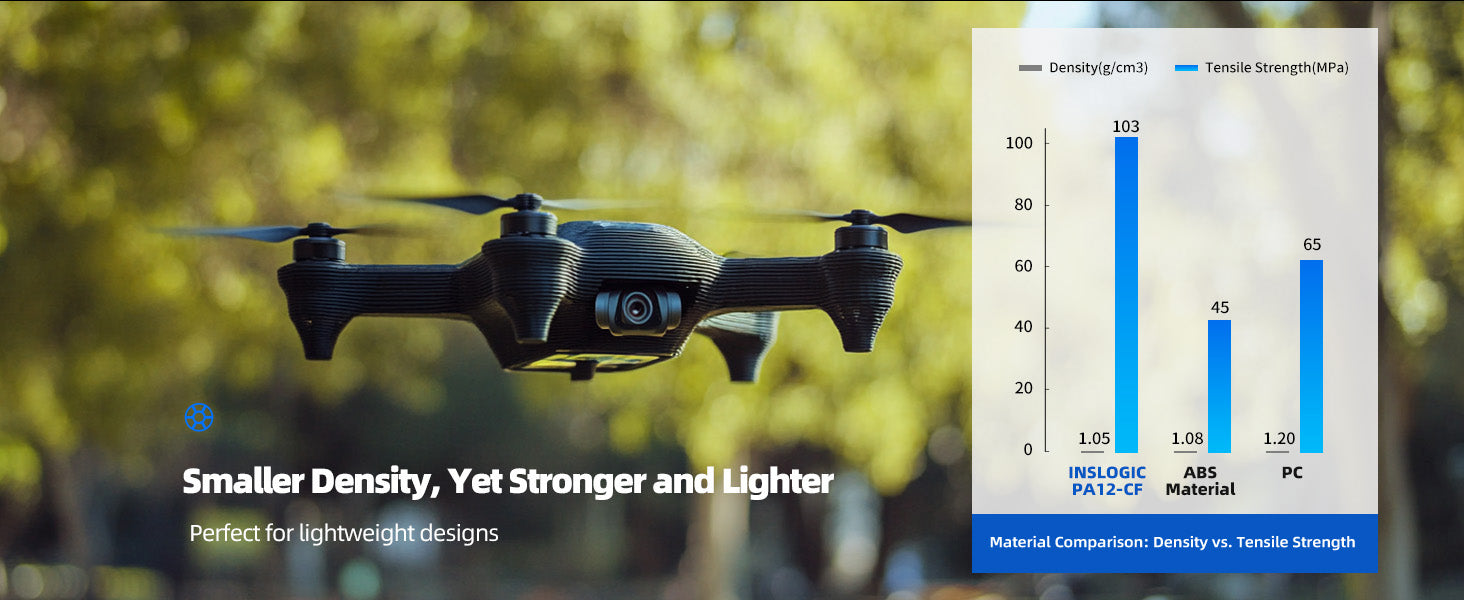

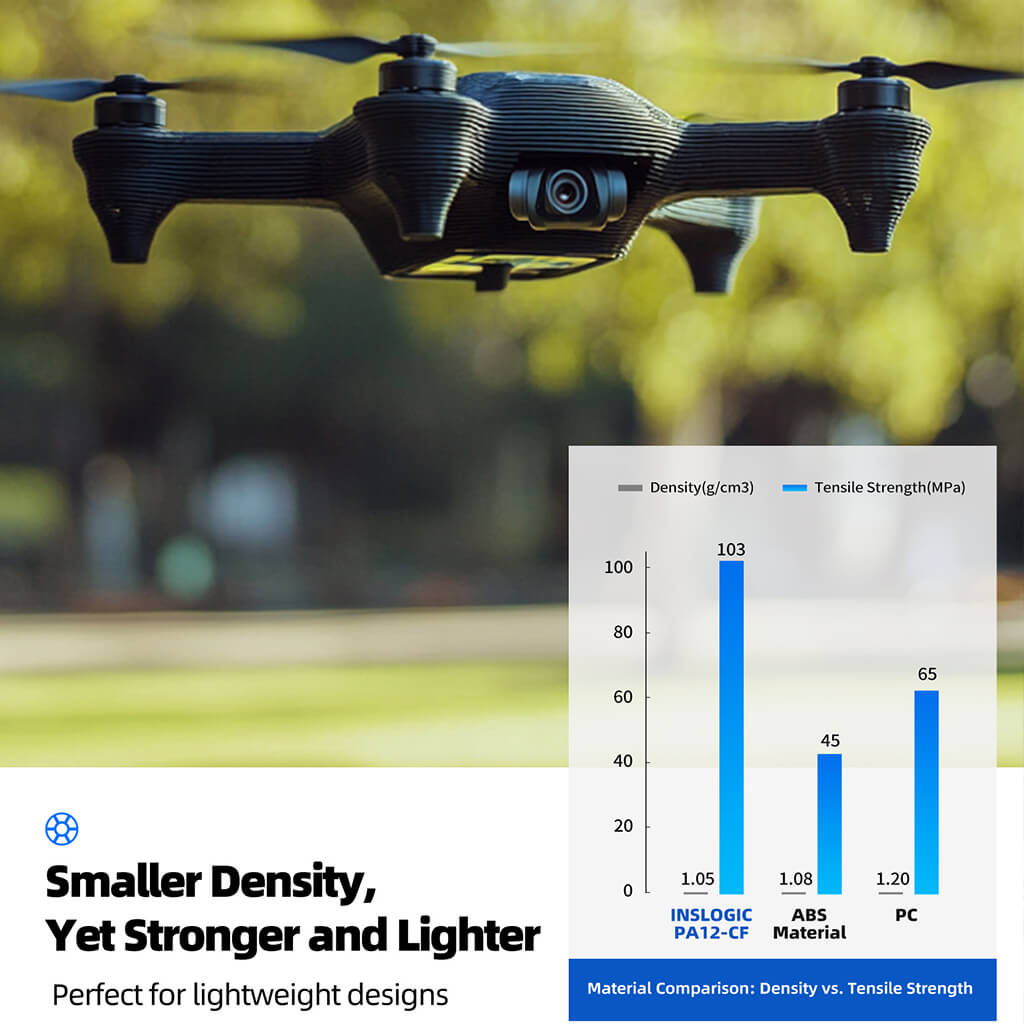

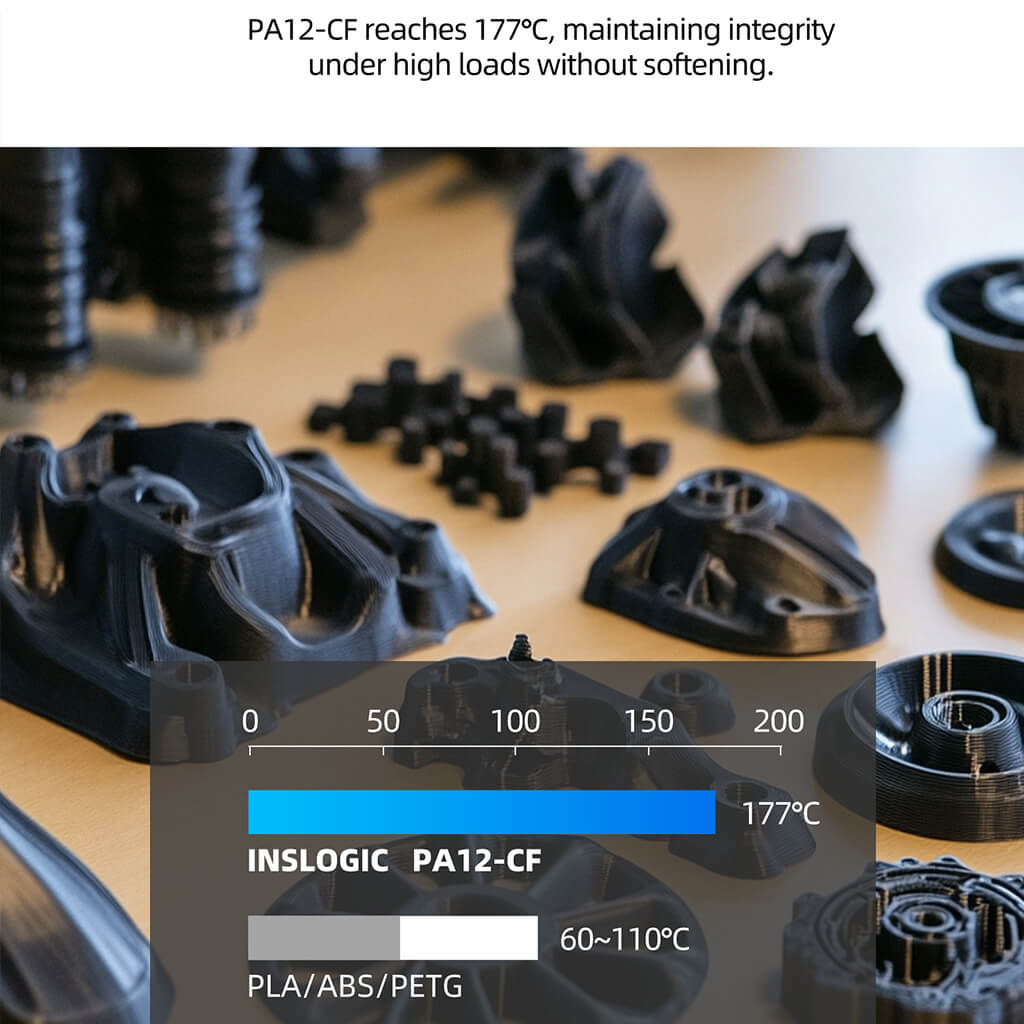

PA12-CF: Lower density material with superior mechanical properties

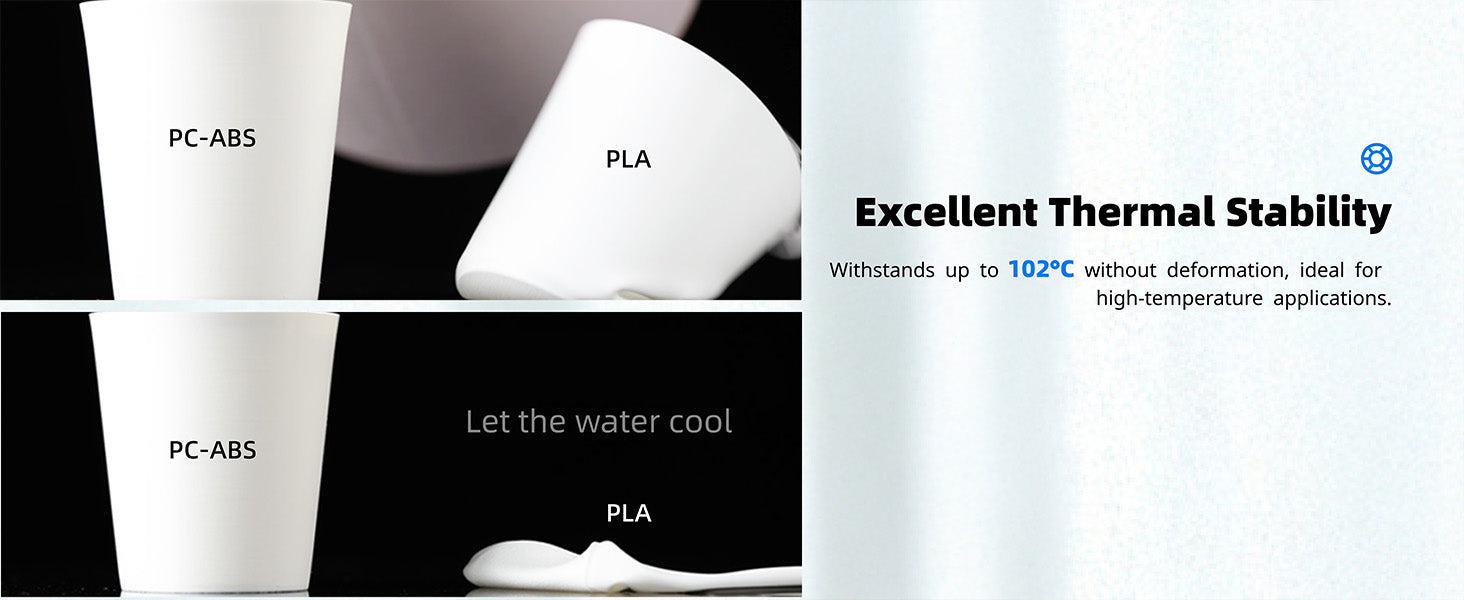

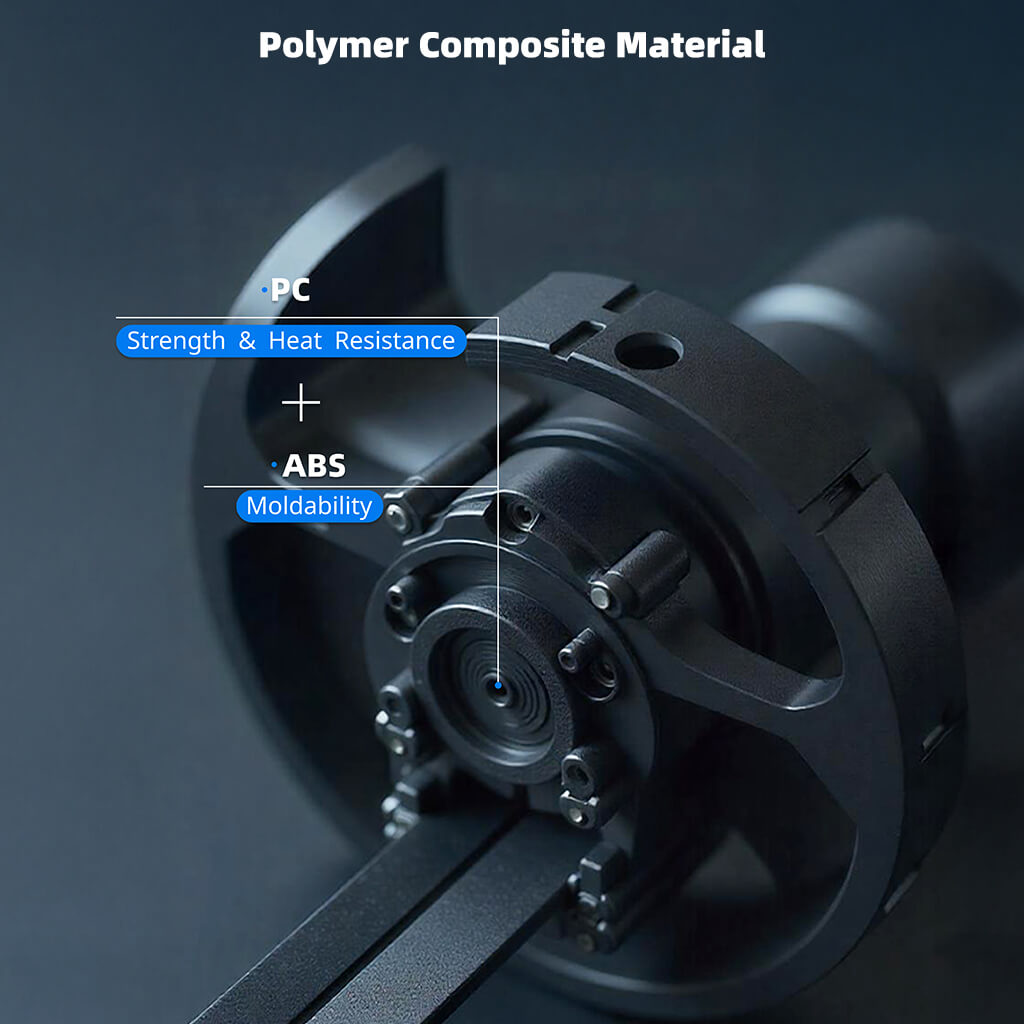

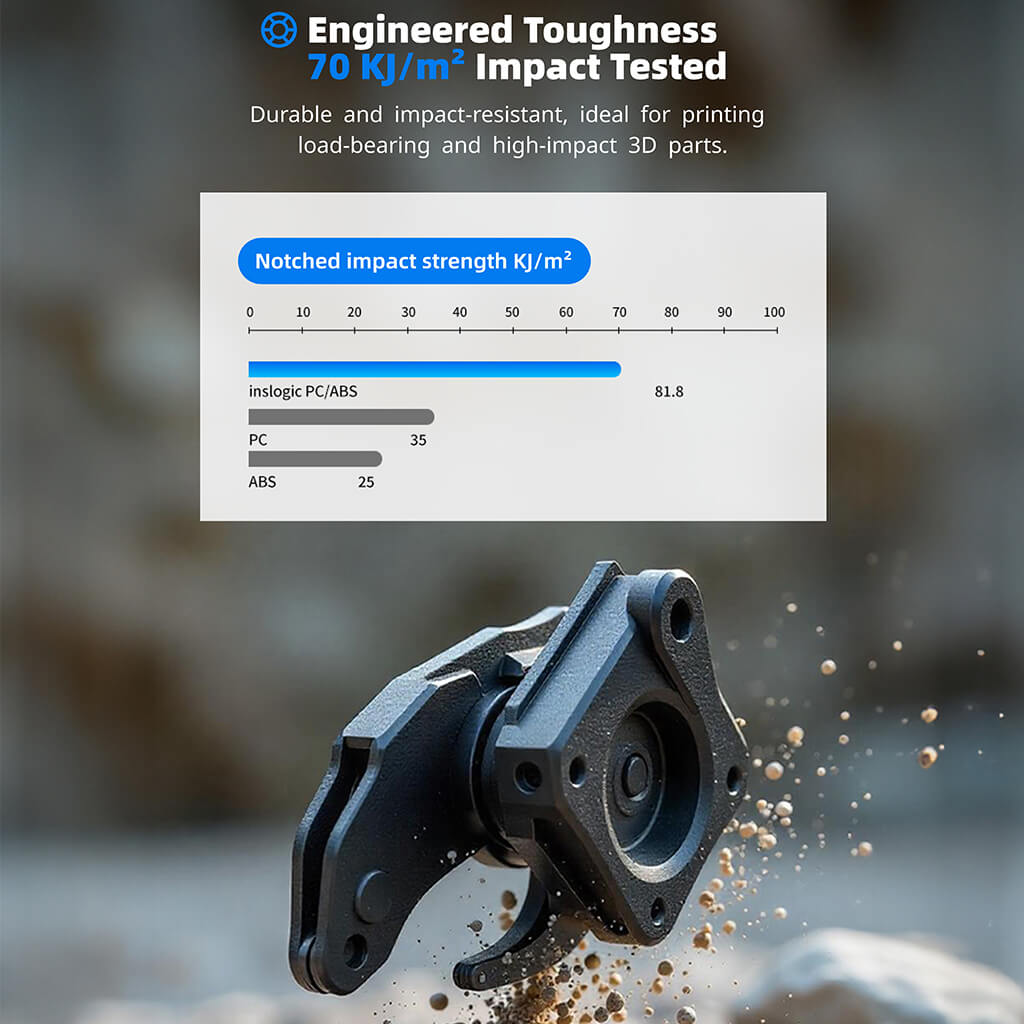

PC-ABS: PC's Strength & Heat Resistance + ABS's Moldability

Note: Filament types are randomly selected and cannot be chosen.

- Drying Settings: 80 °C for 48h, 110 °C for 3h

- Nozzle Size: 0.2, 0.4, 0.6 mm

- Nozzle Temperature & Printing Speed: 250-270 °C at a speed of 50-100 mm/s, and 270-280 °C at a speed of 100-150 mm/s

- Bed Temperature: 30 - 50 °C

- Cooling Fan Speed: 100%

- Bed Type: Textured PEI Sheet

- Glue: Recommended for larger prints

- Heated chamber: Recommended for larger prints

* The settings displayed above are intended as guidance to help you find your optimal print settings. These ranges in settings should work for most printers. Each desktop 3D printer has its own characteristics and requires fine-tuning and optimization of these settings to achieve the best printing results.

- Drying Settings: 90 °C for 12h; 110 °C for 4h

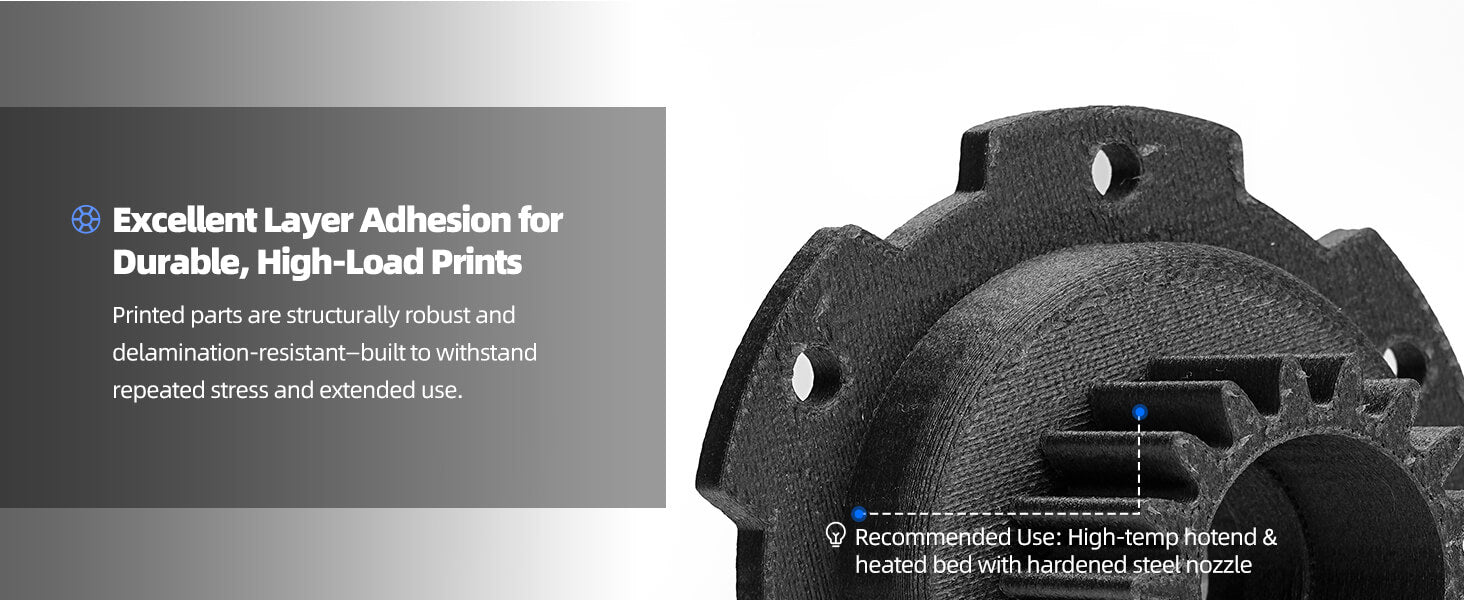

- Nozzle: Hardened steel nozzle with a diameter of 0.4 or 0.6 mm

- Nozzle Temperature & Printing Speed: 270-290 °C at 50-100 mm/s

- Bed Temperature: 50 - 70 °C

- Cooling Fan Speed: 30%

- Bed Type: Textured PEI Sheet

- Annealing Settings: 90 ℃ for 12h, 110 °C for 6h, 130 °C for 3h

* The settings displayed above are intended as guidance to help you find your optimal print settings. These ranges in settings should work for most printers. Each desktop 3D printer has its own characteristics and requires fine-tuning and optimization of these settings to achieve the best printing results.

- Drying Settings: 110 °C for 4h

- Nozzle: Hardened steel nozzle with a diameter of 0.4 or 0.6 mm

- Nozzle Temperature & Printing Speed: 270-290 °C at 50-120 mm/s

- Bed Temperature: 50 - 70 °C

- Cooling Fan Speed: 100%

- Bed Type: Textured PEI Sheet

- Annealing Settings: 110 °C for 6h

* The settings displayed above are intended as guidance to help you find your optimal print settings. These ranges in settings should work for most printers. Each desktop 3D printer has its own characteristics and requires fine-tuning and optimization of these settings to achieve the best printing results.

- Drying Settings: 90 °C for 12h; 110 °C for 4h

- Nozzle: Hardened steel nozzle with a diameter of 0.4 or 0.6 mm

- Nozzle Temperature & Printing Speed: 260-280 °C at 60-100 mm/s

- Bed Temperature: 60 - 70 °C

- Cooling Fan Speed: 70%

- Bed Type: Textured PEI Sheet

- Annealing Settings: 90 ℃ for 12h, 110 °C for 6h, 130 °C for 3h

* The settings displayed above are intended as guidance to help you find your optimal print settings. These ranges in settings should work for most printers. Each desktop 3D printer has its own characteristics and requires fine-tuning and optimization of these settings to achieve the best printing results.

- Drying Settings: 70-80 °C, 6h

- Nozzle Size: 0.2, 0.4, 0.6 mm

- Nozzle Temperature & Printing Speed: 260-280 °C at 50-230 mm/s.

- Bed Temperature: 100 - 110 °C

- Cooling Fan Speed: 100%

- Bed Type: Textured PEI Sheet

* The settings displayed above are intended as guidance to help you find your optimal print settings. These ranges in settings should work for most printers. Each desktop 3D printer has its own characteristics and requires fine-tuning and optimization of these settings to achieve the best printing results.

How to Use Inslogic Reusable Spool and Refill

FAQ

Shipping

It depends on where you are.

Within our delivery locations, all packages are shipped via USPS, DHL, FedEx, DPD, or UPS and will arrive within 3-10 business days (except for pre-sale items).

United States: 3-7 business days

Germany: 1-3 business days

Other Europe Contury: 3-10 business days

United Kingdom: 2-4 business days

Delivery details will be provided in your confirmation email. Check delivery location here.

About Filament

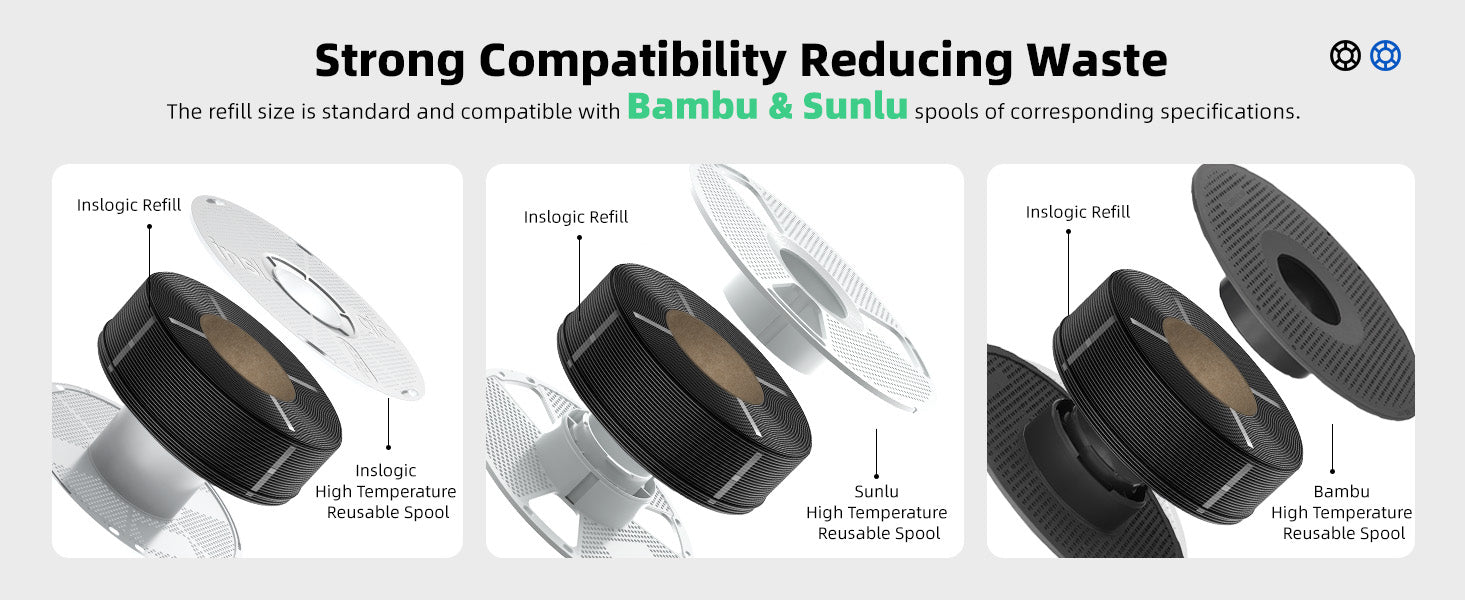

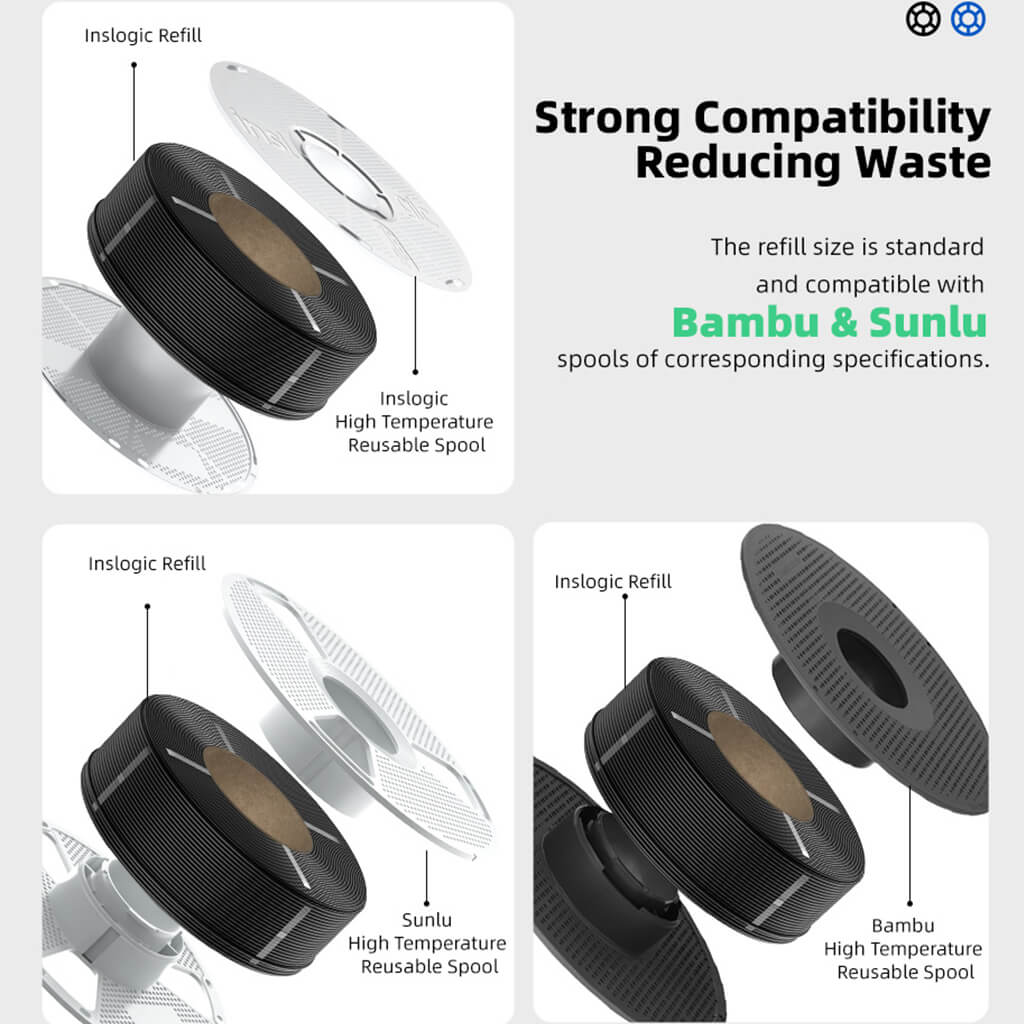

Inslogic Refill Filament compatible with Bambu Reusable Spool and Sunlu Third-Generation Reusable Spool.

It is recommended to keep them in a dry and cool place, away from direct sunlight and moisture.

Consider using vacuum-sealed bags to keep moisture, odors, and bugs away.

The quality of your prints depends on both the printer and the filament used.

To achieve the best results, it's advisable to fine-tune the slicing parameters to discover the optimal settings for various filaments and printers.

- The nozzle might be too distant from the bed.

- Ensure that your heated bed is both level and clean.

- Additionally, confirm that your printing and bed temperatures are within the correct range; Adjust them if necessary.

When working with specialty filaments like ABS, ASA, and others, consider reducing the first layer print speed to enhance your chances of success.