Inslogic PEEK Filament 1.75mm

Choose options

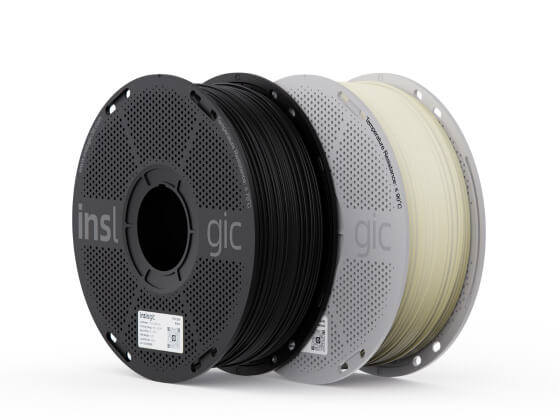

- Metal-Like Strength & Reliability: Provides exceptional toughness and durability, ideal for parts that must withstand repeated stress and heavy loads.

- High Heat Resistance: Maintains dimensional and mechanical stability under continuous service temperatures up to 240°C.

- Excellent Chemical Resistance: Resists fuels, solvents, and hydrolysis, keeping printed parts strong, safe, and reliable in even the harshest environments.

- Flame Retardant & Safe: UL94 V-0 rated and self-extinguishing, protecting printed parts from fire hazards in high-temperature applications.

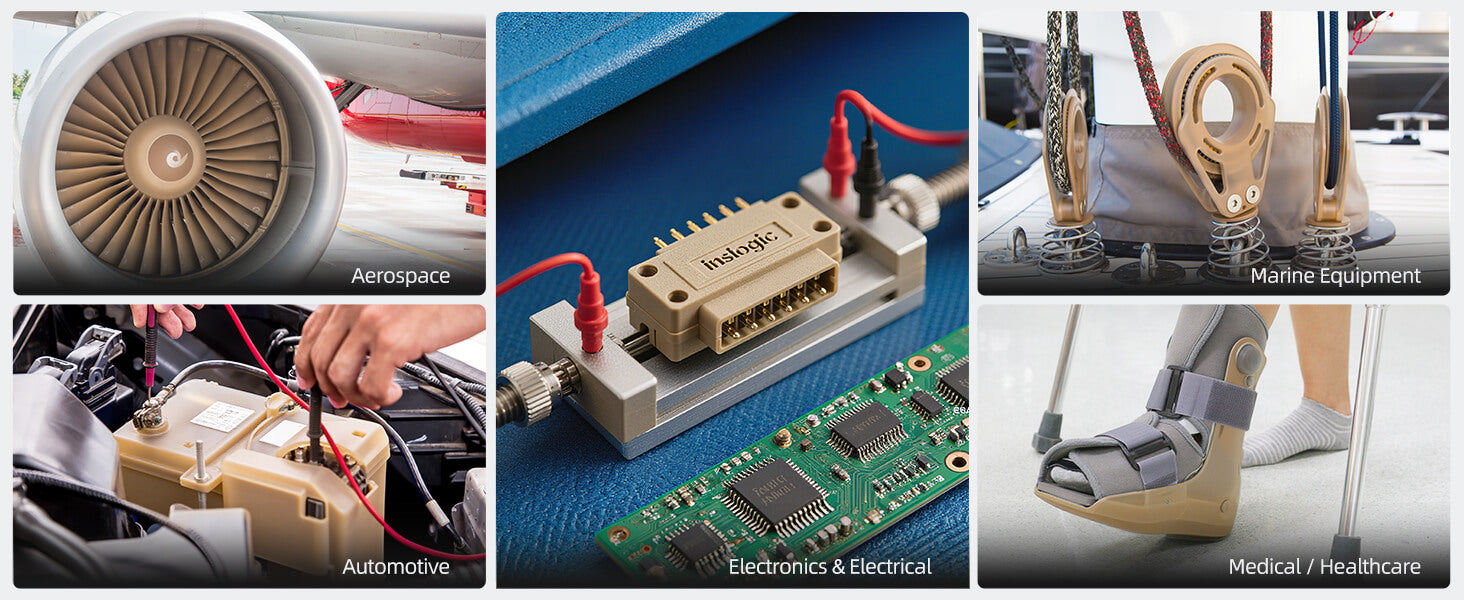

- Industrial-Grade PEEK Filament: High-performance filament engineered for demanding applications in aerospace, automotive, and medical 3D printing.

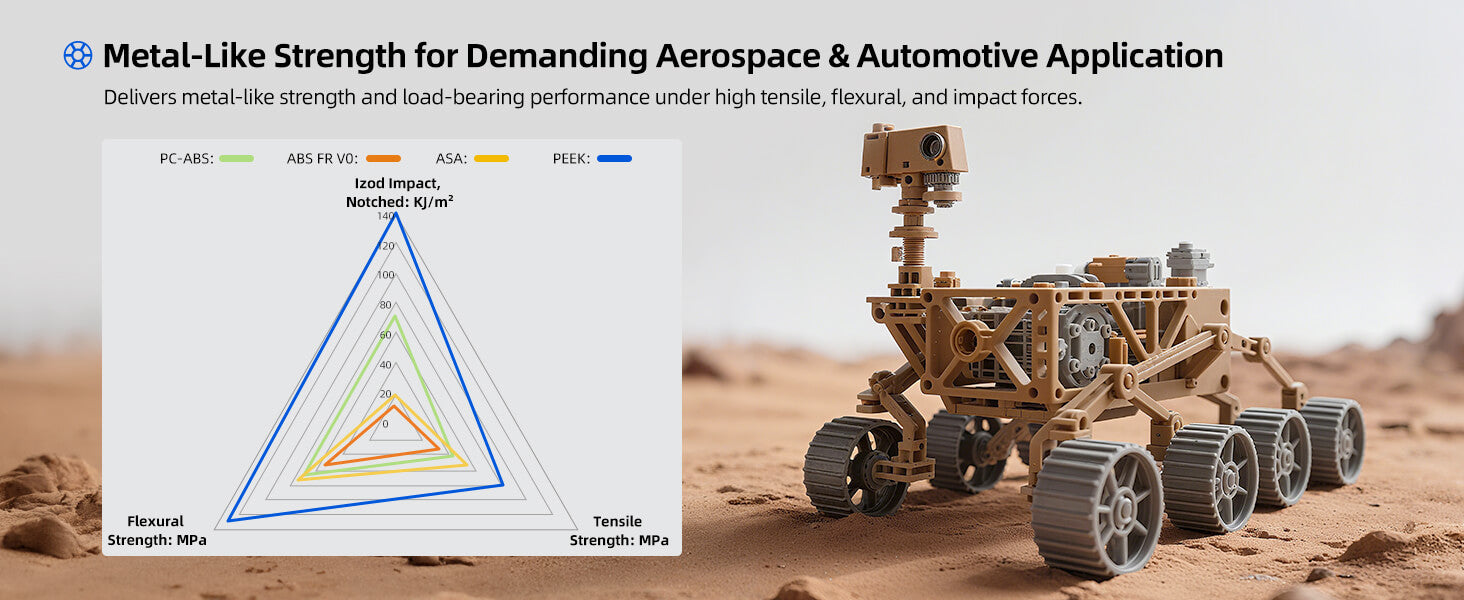

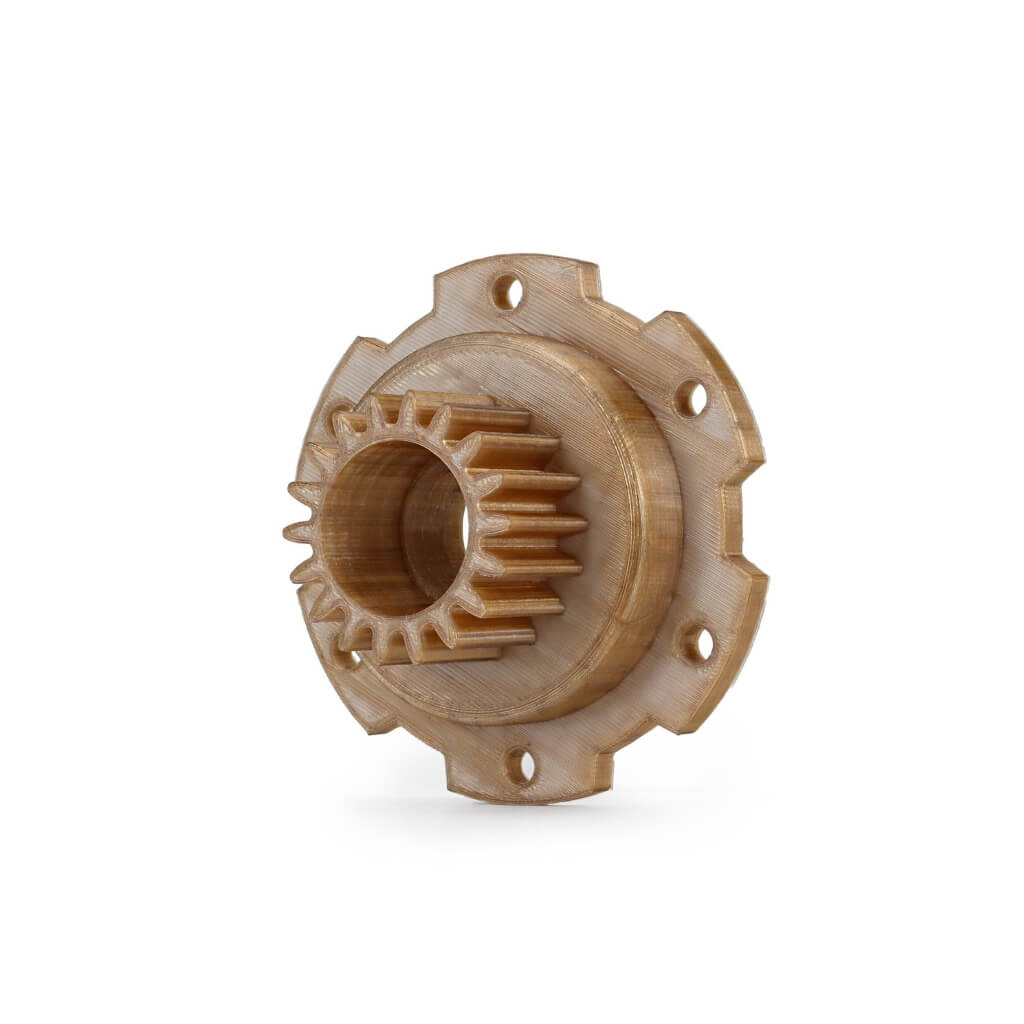

- Excellent Self-Lubrication & Fatigue Resistance: Ideal for gears, bearings, housings, and other functional components requiring fatigue and wear resistance.

- Applications: Aircraft Turbine, Car Battery Housing, Ship Parts, Orthopedic Implants, Medical Fixture

PEEK (Polyether Ether Ketone) is one of the highest-performance engineering thermoplastics in the world. It is known for its exceptional mechanical, thermal, and chemical resistance properties, outpacing many metals and composites, and offering lightweight solutions for demanding applications across various industries.

Superior Mechanical Properties. With a tensile strength of 80 MPa, flexural strength of 130 MPa, and impact resistance of 140 kJ/m², PEEK offers metal-like performance. It provides weight-saving benefits, reduces fuel consumption and emissions, and is ideal for aerospace, automotive, marine, medical, and energy applications.

Inherent Flame Resistance (UL94 V-0). PEEK maintains flame resistance, making it suitable for high-temperature environments. It can withstand short-term service temperatures up to 260°C and continuous exposure up to 240°C. Its strong layer bonding ensures excellent dimensional accuracy and z-strength.

Chemical Resistance. PEEK is highly resistant to oils, automotive fluids, halogenated hydrocarbons, alcohols, and aqueous solutions. It shows exceptional resistance to hydrolysis in hot water and is nearly insoluble in most common solvents.

Medical Applications. PEEK is biocompatible, biostable, and x-ray transparent. It’s widely used in medical implants, particularly in orthopedic and spinal applications, due to its durability and resistance to wear and chemical degradation.

- Length: 320 m

- Net Weight: 1 kg

- Diameter: 1.75 mm ± 0.03 mm

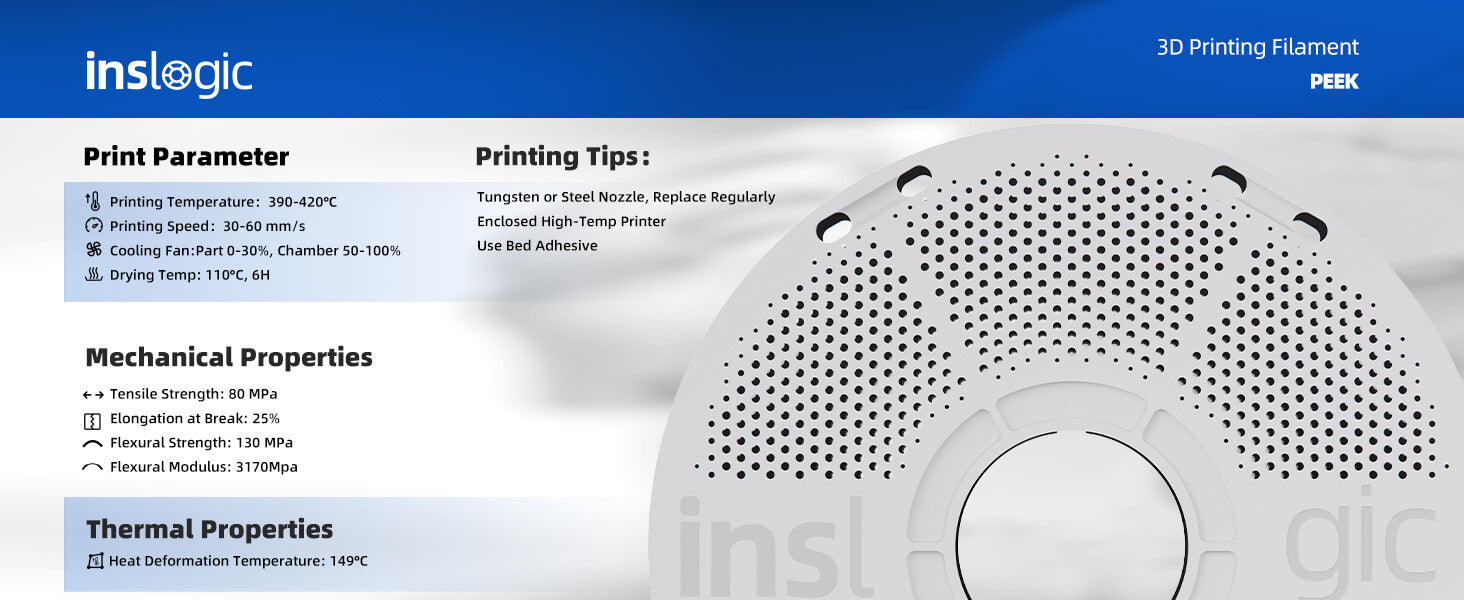

- Tensile Strength: 80 MPa

- Elongation at Break: 25%

- Flexural Strength: 130 Mpa

- Flexural Modulus: 3170 Mpa

- Density: 1.1965 g/cm³

- Izod Impact, Notched: 140 KJ/m²

- Heat Deflection Temperature at 0.45 MPa: 149 ℃

------------------------

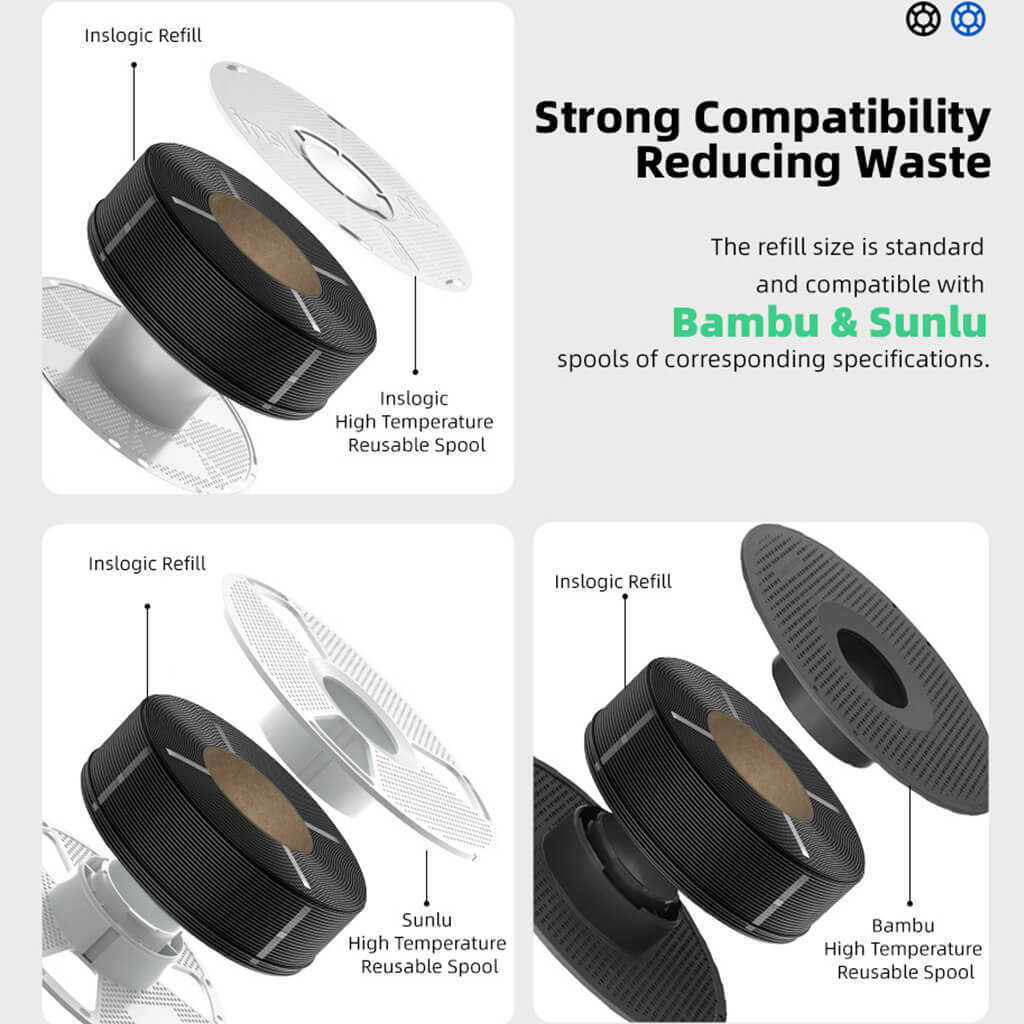

1 kg Reusable Spool Specifications:

- Materials: PC

- Color: White grey

- Temperature Resistance: ≤110℃

- Spool & Cardboard Coil Weight: 232 ± 3 g

- Inner Hole Diameter: 55±0.1 mm

- Outer Diameter: 200±0.1 mm

- Width: 67±0.1 mm

* All specifications have been tested in a laboratory. Please note that material properties may vary based on part geometry, print orientation, print settings, and temperature.

- Drying Settings: 110 °C, 6h

- Nozzle Size: 0.4, 0.6 mm

- Nozzle Temperature & Printing Speed: 390-420 °C at 30-60 mm/s.

- Bed Temperature: 100 - 120 °C

- Cooling Fan Speed: Part 0-30%, Chamber 50-100%

- Bed Type: Carbon fiber build plate

* The settings displayed above are intended as guidance to help you find your optimal print settings. These ranges in settings should work for most printers. Each desktop 3D printer has its own characteristics and requires fine-tuning and optimization of these settings to achieve the best printing results.

How to Use Inslogic Reusable Spool and Refill