2026 Material Validation Kickoff

What’s in the Lab

Small coils. Quick decisions.

Mix & Match

Lab Deals

250g: 3+ save 22% | 6+ save 26%

500g: 2+ save 24% | 4+ save 27%

Auto-discount in cart.

Test small, learn fast, commit with confidence.

Choose Your Test Mission

Lab Notes

What Actually Affects Results

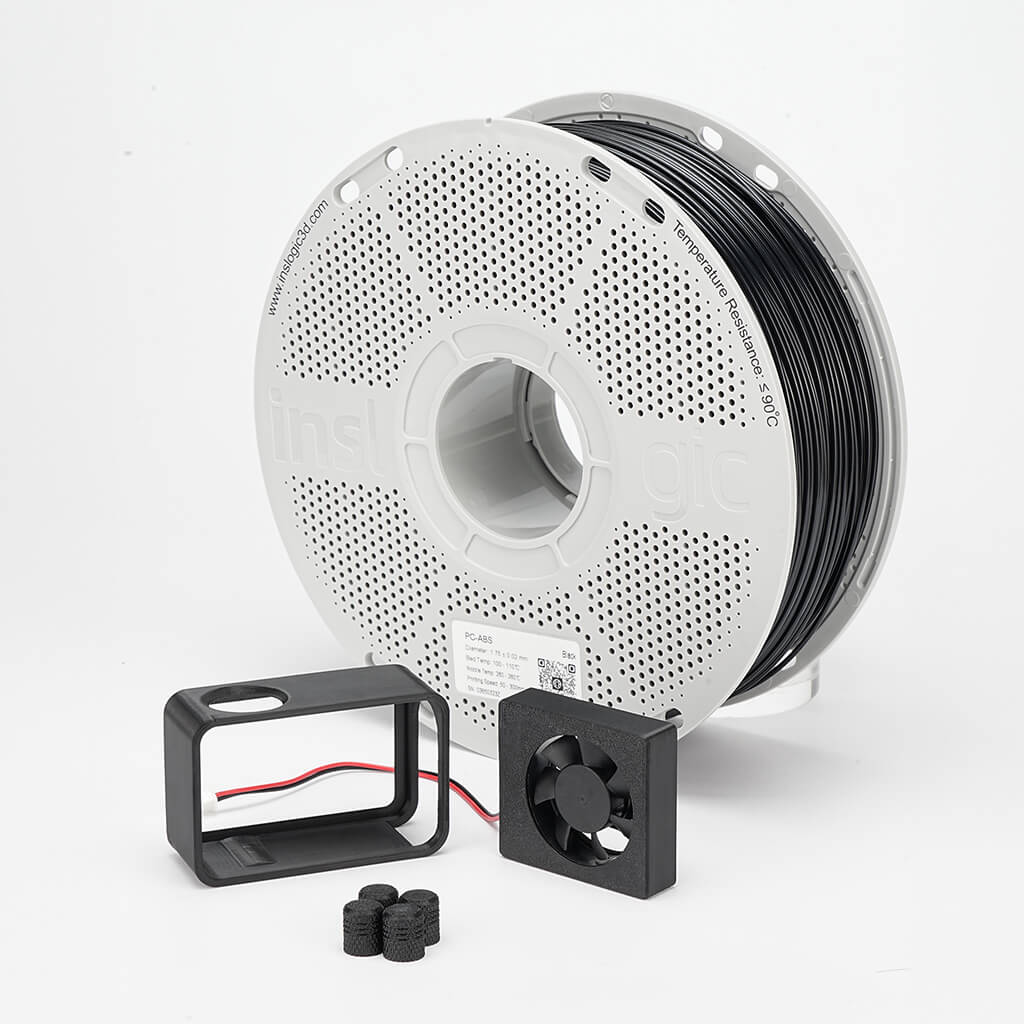

PC-ABS

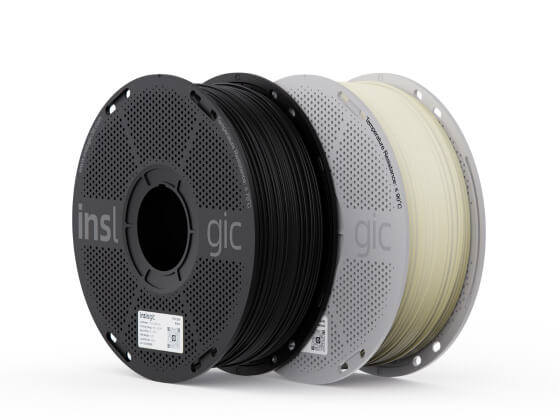

High-performance materials engineered for precision and durability in every print.

PA6/66

Advanced formulations tested to meet the highest industry standards.

PA6-GF25

Consistent performance across a wide range of applications and environments.

PA6-CF

Dedicated technical assistance to help you achieve optimal printing outcomes.

PA12-CF

Trusted by professionals worldwide for mission-critical 3D printing projects.

Scoreboard: Relative Performance

Material Print Settings

Drying Settings: 70-80 °C, 6h

Nozzle Size: 0.2, 0.4, 0.6 mm

Nozzle Temperature & PrintingSpeed: 260-280 °C at 50-230 mm/s.

Bed Temperature: 100 - 110 °C

Cooling Fan Speed: 100%

Bed Type: Textured PEI Sheet

- Drying Settings: 80 °C for 48h, 110 °C for 3h

- Nozzle Size: 0.2, 0.4, 0.6 mm

- Nozzle Temperature & Printing Speed: 250-270 °C at a speed of 50-100 mm/s, and 270-280 °C at a speed of 100-150 mm/s

- Bed Temperature: 30 - 50 °C

- Cooling Fan Speed: 100%

- Bed Type: Textured PEI Sheet

- Glue: Recommended for larger prints

- Heated chamber: Recommended for larger prints

- Drying Settings: 110 °C for 4h

- Nozzle: Hardened steel nozzle with a diameter of 0.4 or 0.6 mm

- Nozzle Temperature & Printing Speed: 270-290 °C at 50-120 mm/s

- Bed Temperature: 50 - 70 °C

- Cooling Fan Speed: 100%

- Bed Type: Textured PEI Sheet

- Annealing Settings: 110 °C for 6h

- Drying Settings: 90 °C for 12h; 110 °C for 4h

- Nozzle: Hardened steel nozzle with a diameter of 0.4 or 0.6 mm

- Nozzle Temperature & Printing Speed: 270-290 °C at 50-100 mm/s

- Bed Temperature: 50 - 70 °C

- Cooling Fan Speed: 30%

- Bed Type: Textured PEI Sheet

- Annealing Settings: 90 ℃ for 12h, 110 °C for 6h, 130 °C for 3h

- Drying Settings: 90 °C for 12h; 110 °C for 4h

- Nozzle: Hardened steel nozzle with a diameter of 0.4 or 0.6 mm

- Nozzle Temperature & Printing Speed: 260-280 °C at 60-100 mm/s

- Bed Temperature: 60 - 70 °C

- Cooling Fan Speed: 70%

- Bed Type: Textured PEI Sheet

- Annealing Settings: 90 ℃ for 12h, 110 °C for 6h, 130 °C for 3h

Short reads that save long hours of trial-and-error.

Lab Journal

Lab FAQ

Everything you need to know about samples, setup, and discounts.

Samples & Compatibility

They are lighter, spool-free coils designed for trials—great for fit checks, prototypes, and material comparison before buying full spools.

We recommend using a reusable spool or spool holder. A simple adapter works for most setups.

The recommended profiles are tuned for Bambu Lab printers (X1 / P1 / A1). Other printers can work, but may require tuning.

Yes—this program is designed to make engineering materials easier to start. Follow the recommended settings and drying guidance for best results.

Program & Discounts

Discounts apply automatically at checkout based on the quantity in your cart.

The highest qualified tier will apply (it won’t stack with the lower tier).

Yes—mix & match across the Engineering Sample materials within the same weight series (250g or 500g).

No—tiers are calculated separately for each weight series.

Shipping

We currently ship to the United States, Europe (except UK), and the United Kingdom.

US orders ship from Kentucky. EU orders ship from Frankfurt (Germany). UK orders ship from Luton.

Processing time: 1–3 business days.

Delivery time:

- US: 3–7 business days

- EU: 3–10 business days

- UK: 3–7 business days

Shipping is free for most destinations, and any additional shipping fees (if applicable) will be shown at checkout.

Returns & Support

You can return purchased items to Inslogic within 14 days of the date they were shipped to you. After 14 days, we do not accept returns.

Items must be unused, undamaged, complete, and in the original packaging. Some consumables may not be eligible once opened (per policy).

Use the chat widget or email our support team. If possible, include your printer model, material, and photos of the issue.